The most efficient methodology to generate energy in the cleanest and most environmentally sustainable way is currently the challenge that has global companies busy. Just as this project succeeds in creating green electricity, now the controversial nuclear energy sector is surprising with a new technology that includes precious metals and powerful lasers that simulate the sun.

Nuclear power faces the challenge of optimizing its traditional methods for the creation of cleaner electricity.

An experiment in California in late 2022 has opened a futuristic portal for power plants through the reaction and fusion response used in nuclear plants, but with minimal proportions to create pollution-free electric current.

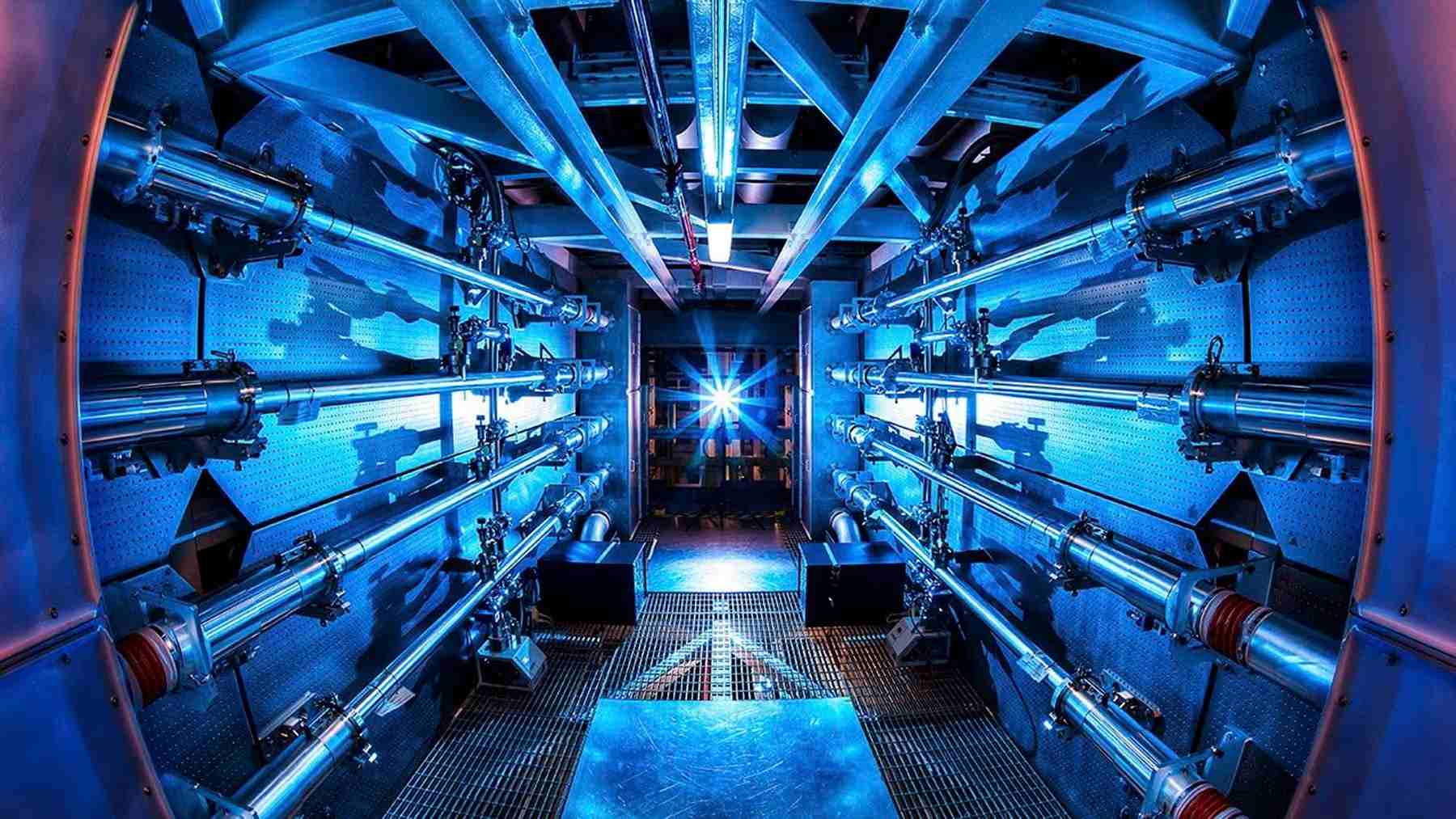

The National Ignition Facility (NIF) at Lawrence Livermore National Laboratory (LLNL) has come up with an innovative formula that revolutionizes the way electricity is created through the inclusion of elements of nuclear power.

The new compound tested by the scientists included a tiny diamond sphere covering a fuel capsule inside, which, when exposed to 192 laser beams, generated a higher proportion of nuclear energy and temperature than ever before.

Researchers who for decades have been carrying out new experiments trying to improve the systems of production of cleaner electrical energy, developed new mechanisms of reaction and fusion obtaining a greater amount of energy than that demanded by lasers.

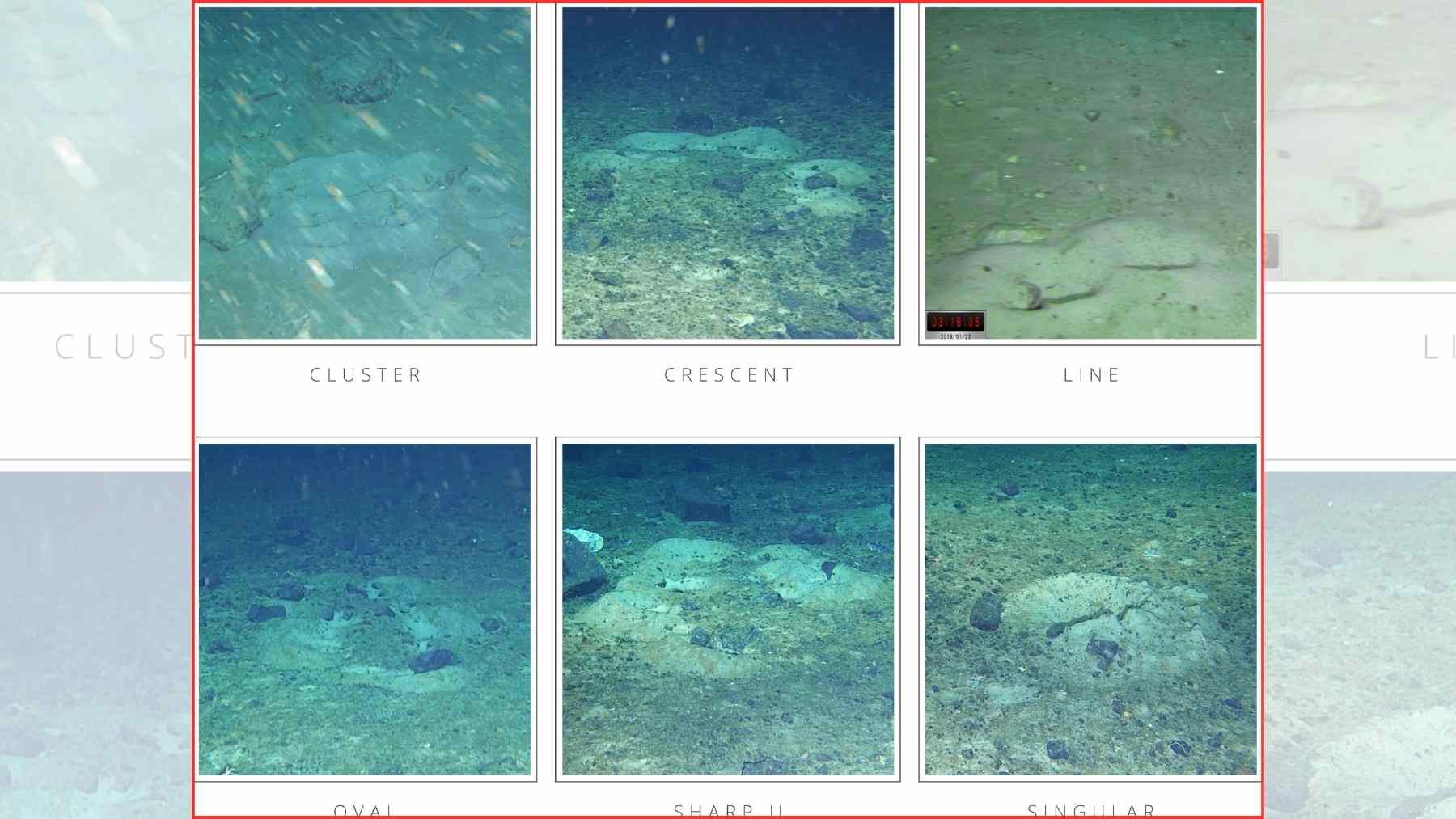

Components of the experiment to improve nuclear energy production techniques

The constituent elements of this new formulation undergo very meticulous pre-processing before they are ready for artificial exposure to lasers that simulate the sun’s rays. In particular, the small diamond cylinder must meet certain essential technical requirements.

These specifications, which are necessary for a diamond the size of a peppercorn, must ensure that the surface is as smooth as possible, avoiding any porosity, relief or impurity that could cause any defect when exposed to light.

For this reason, it is necessary to import these spheres from Germany, manufactured by Diamond Materials, located in Freiburg, Germany.

Processing of the diamond sphere suitable for nuclear energy fusion

The diamond factory assures that the processing of this type of material is very intense and the demand is very high, which requires complex work that can take up to two months to obtain a series of 20 to 40 capsules.

The technique used for the manufacture of these synthetic diamond spheres of chemical vapor deposition, allows to reach the requirements of polishing to smooth the surface with a final glazed layer of diamond crystals to achieve a perfect finish.

The capsules contain a silicon carbide core inside, which upon arrival at the laboratory is replaced by heavy hydrogen isotopes such as deuterium and tritium, which cause a stronger reaction to light.

The core is then bathed with a layer of gold and depleted uranium, and as a final protective layer, an aluminum coating is incorporated with the capacity to cool the inner components prior to the reaction. In addition, optical technologies are used to encourage light exposure.

The research that opened the door to the future earlier than expected.

“The experiment caused a paradigm shift in the scientific community. Ignition was thought to be almost unattainable or that it could only happen 40 years in the future,” said Mike Farrell, vice president of inertial fusion technology at General Atomics, LLNL’s largest industrial partner.

This is an excellent first step in perfecting nuclear energy technology, spurring the arrival of government and corporate funding to continue system optimization. We’ll be keeping a close eye on the project’s progress as we show you a nuclear plant that has a shutdown date.