Germany is well-known for its forward-thinking industrial innovation, and its future energy strategy is no exception. As the world seeks sustainable solutions, Germany has decisively turned towards methanol, moving away from hydrogen as the primary fuel of the future. Produced from renewable sources and paired with electric powertrains, methanol promises to be a key player in decarbonizing the transportation sector. The shift is part of Germany’s broader ambition to achieve net-zero CO2 emissions, while ensuring that current infrastructure remains usable.

Why methanol outshines hydrogen and fossil fuels in the future energy race

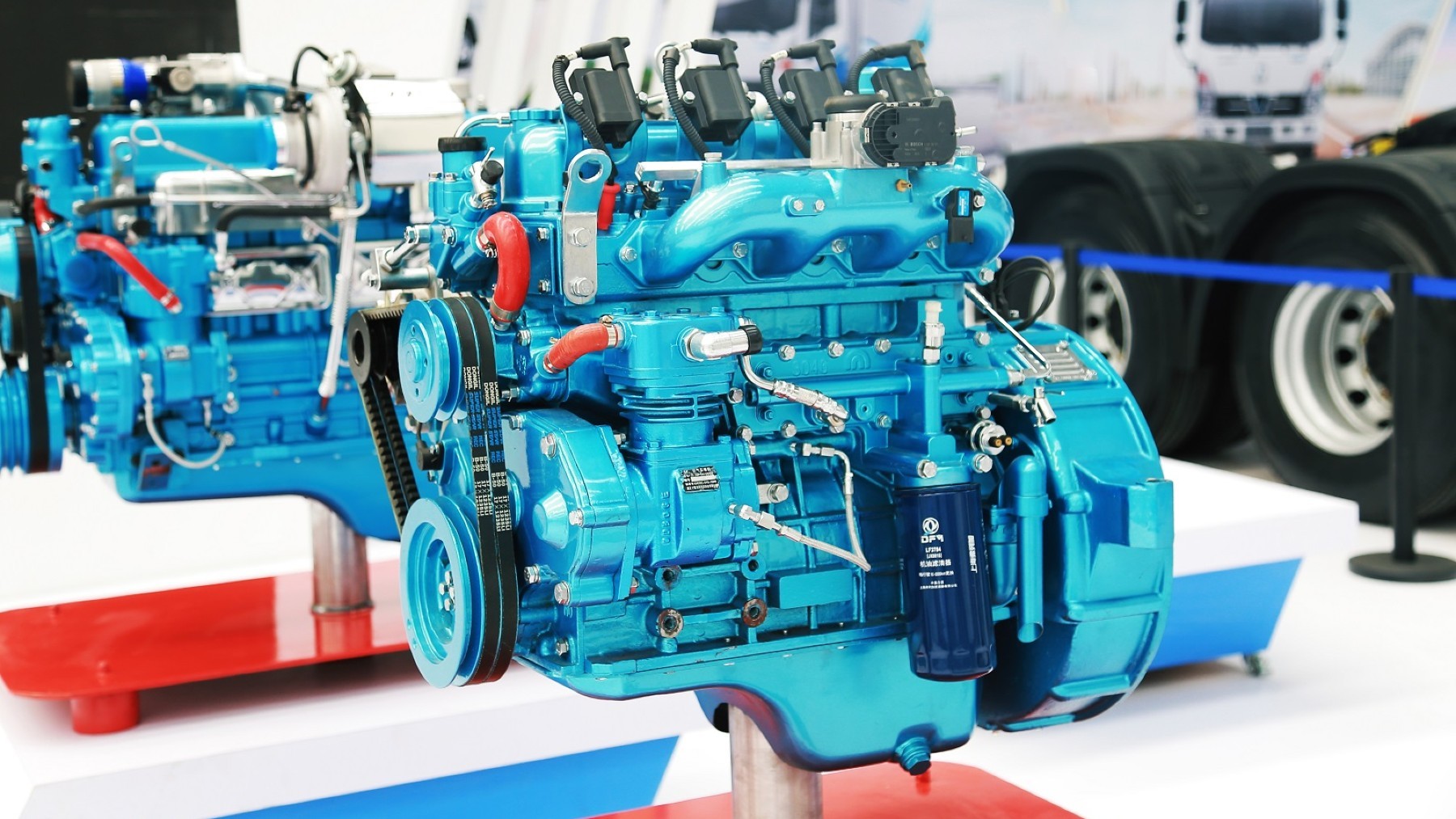

Germany’s focus on methanol is based on its numerous advantages compared to hydrogen and traditional fossil fuels. One significant benefit of methanol is its high enthalpy of vaporization, which results in lower combustion temperatures compared to gasoline, leading to less heat loss and a reduced risk of pre-ignition. This translates into improved efficiency, which is comparable to diesel engines. In combination with electric powertrains, methanol-powered vehicles can achieve brake efficiencies above 40%, with minimal emissions even during cold starts.

Germany’s energy dependency has long been a concern, with 60-70% of its energy needs being met by imports. Methanol offers a solution to this problem, as it can be synthesized from renewable hydrogen and recycled CO2, reducing reliance on foreign energy. With a high volumetric energy density and liquid state at standard conditions, methanol is also easier to store and transport using existing fuel infrastructure.

Hydrogen infrastructure: Why Germany is choosing methanol for a smoother energy transition

Although hydrogen is a clean energy source, its infrastructure and storage challenges make it less practical. Hydrogen must be kept at very low temperatures to stay liquid, requiring massive investments to build the necessary infrastructure. Methanol, however, is already compatible with existing fuel systems and can be transported using conventional tankers and trucks. This ease of integration is one of the reasons methanol is more favored in Germany’s energy strategy.

Additionally, methanol’s higher volumetric energy density compared to hydrogen is a major factor in its selection. While liquefied hydrogen holds around 2.34 kWh per liter, methanol stores 4.4 kWh per liter, offering more energy storage per volume. This efficiency is vital for Germany’s automotive industry, which seeks to balance energy supply with vehicle consumption.

Methanol’s environmental edge: How it fits into Germany’s carbon-neutral ambitions

Germany’s climate goals require more than just reduced emissions—they demand a fuel that integrates into a closed carbon cycle. Methanol, synthesized from hydrogen and captured CO2, fits the bill perfectly. Obrist Powertrain, a German innovation firm, has developed a patented production process for methanol that removes more CO2 from the atmosphere than is released during combustion.

Compared to traditional fuels, methanol-powered vehicles have clear advantages in emissions, emitting fewer NOx and particles. This reduction in harmful pollutants is crucial for urban areas, where air quality remains a pressing concern. Methanol’s high compression ratio also allows for improved engine efficiency without knocking, further aiding in CO2 reduction while still delivering adequate power and torque for vehicles.

Germany’s e-fuels strategy: A balanced approach to decarbonization without scrapping existing infrastructure

While methanol is a key focus, it is just one aspect of Germany’s comprehensive strategy to develop alternative fuels known as e-fuels or atmospheric fuels (aFuels). These fuels, produced using renewable energy, are designed to be carbon neutral and can be used in existing combustion engines. This approach allows for a smoother transition, avoiding the need to discard over a billion vehicles that would otherwise be required in an all-electric future.

E-fuels, including methanol, align with Germany’s desire to utilize its current infrastructure. The cost and disruption of transitioning entirely to electric vehicles can be mitigated with the use of methanol and other e-fuels. Obrist’s methanol production process, which uses solar and wind energy in desert areas, further demonstrates how this innovative solution is both sustainable and scalable.