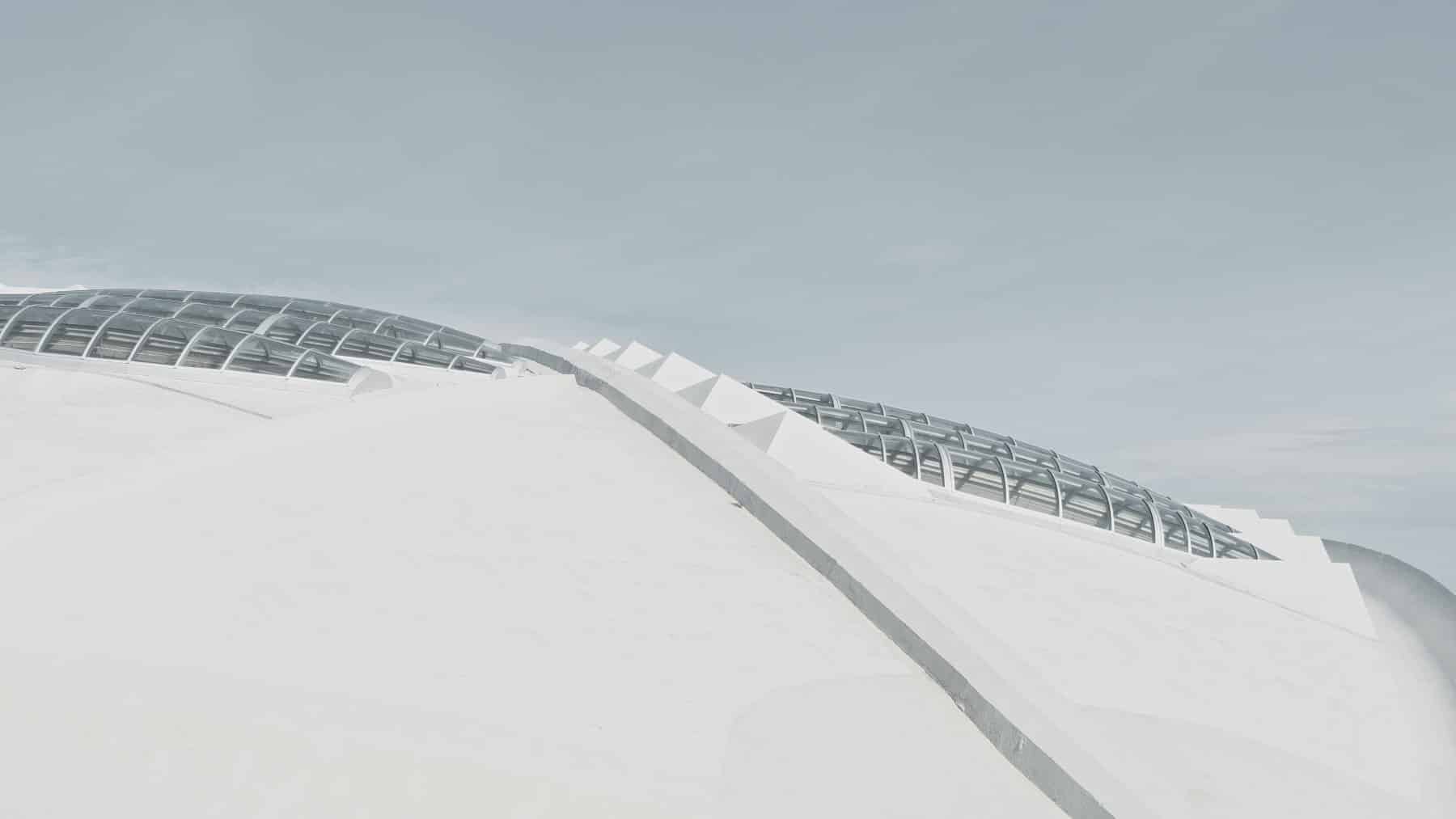

Germany achieved a remarkable renewable energy milestone by running the 1,000th series production of main bearings for multi-megawatt turbines at Thyssenkrupp Rothe Erde facilities. By reaching this historic production threshold, the nation demonstrates its dedication to renewable energy as the world’s largest wind power market.

Germany established its place in renewable energy history with the 1,000th mass-produced main bearing

The achievement is proof of national investments in modern renewable technologies that ensure sustainable energy security while reducing coal and oil dependency. Germany’s exceeding the production threshold displays its ability to upgrade wind power technology through engineering at the same level. Through these developments, Germany will create local jobs and develop green technologies, establishing itself as the world’s renewable energy leadership destination.

The achievement meets European Union climate goals for carbon neutrality while supporting world efforts toward becoming carbon neutral. Germany positions itself to lead the world in developing future sustainable energy systems as it progresses as a nation. ThyssenKrupp rothe erde reached a milestone by delivering its 1,000th multi-megawatt main bearing in March 2020. (Also, read about this turbine)

The main bearing functions as the fundamental component in wind turbine drive train operation since it facilitates the seamless transfer of wind-generated energy to the generator. The drive train system revolves around this component because it allows the turbine to receive primary tensional loads and torsional torques. One single-row or multiple-row main bearing weighs 14 tons, with the largest diameter reaching 7 meters before a clamping or bolting process can install it. The efficiency and reliability of energy generation require raceways to receive either case-hardening or non-slip induction-hardening procedures.

Germany is now Europe’s wind energy leader: these numbers prove it.

Germany is now a worldwide leader in wind power, following wind energy, which surpassed lignite in 2019 to become the country’s main energy source. Wind energy in Germany holds the third worldwide position and leads all nations in Europe because of its 61,405 megawatts installed capacity. The main bearings from ThyssenKrupp rothe erde provide power to 7.5 million homes annually, making Germany the top renewable energy force in the world.

Germany’s ocean-based wind energy potential enhances its overall wind energy capacity. The operational wind turbine fleet exceeds 30,000, but offshore installations represent less than 1,200 units. Such offshore turbines operate most efficiently because they obtain strong winds that remain steady in their operating environment. Every part of offshore structures needs strong anti-corrosion protection and high endurance to extreme conditions during operation.

Wind turbines operating offshore possess rotors with 220-meter diameters alongside blades extending beyond 100 meters. Their construction defies harsh environmental conditions through anti-corrosion protection to resist continuous forceful winds, temperature changes, and strong wave actions, making them among the most durable renewable energy systems.

The three critical components that make wind turbines so efficient

Thyssenkrupp Rothe Erde’s engineering expertise extends beyond the main bearings. It can produce rotor, blade, and azimuth bearings for the nacelle. The components have specialized designs to achieve stability and effective power distribution standards. This bearing component delivers torque power to the generator equipment while maintaining axial and radial force stability. Different wind speeds trigger the blade bearing to manipulate the rotor blade angle position for improved turbine performance.

Relying on the azimuth bearing enables the nacelle to automatically follow wind direction variations for optimized efficiency and performance. The maximum diameter of rotor bearings reaches 7 meters, and manufacturers have single-row and multiple-row designs. In contrast, blade bearings utilize raceways preloaded with wear-resistant cage inserts and ozone—and UV-resistant seals. The durability and functional operation of azimuth bearings depend on single—or double-row four-point contact bearings together with integrated sealing systems.

Germany demonstrates its renewable leadership position by manufacturing the one-thousandth main bearing for multi-megawatt wind turbines in wind energy. Through its advanced infrastructure and technological leadership, Germany is ready to conduct successful wind power ( like this producing energy) operations that supply clean electricity to numerous residential consumers. Through this accomplishment, Germany enhances its energy self-reliance and creates an example that invites other nations to adopt renewable energy initiatives.