For many years, liquid hydrogen engines have been regarded as the future of clean energy propulsion, particularly in the aviation and space industries. Nonetheless, problems associated with efficiency, storage, and cost have been some of the issues that have kept liquid hydrogen engines unpopular for general use despite starting well.

With these issues in the spotlight, America is charting a new path—Hydrogen Combustion Engines, which are even more potent and plausible.

Storing hydrogen at cryogenic temperatures made its usage impractical and expensive

Hydrogen in the liquid state was anticipated to be the future fuel because it is dense in energy and environmentally friendly. But its biggest disadvantage is storage. Liquid hydrogen must be stored at cryogenic temperatures below -253°C, which requires elaborate insulation systems, contributing to added complication and cost.

This cryogenic nature results in high levels of evaporative losses and safety issues. Besides, turning hydrogen into a liquid form is energy-intensive, significantly impacting efficiency. In addition, the constraints in infrastructure have also posed a practical challenge to using liquid hydrogen engines.

Availability and accessibility of refueling facilities and specialized transport are limited and costly to develop. These combined challenges have led to the liquid hydrogen engine becoming less of a mainstream solution for the problems and the need to look at more practical solutions.

How hydrogen combustion engines are solving problems and outperforming their liquid predecessors

The challenges posed by liquid hydrogen have made America shift its attention towards hydrogen combustion engines, a breakthrough in green energy. Hydrogen combustion engines, on the other hand, utilize gaseous hydrogen; thus, fuel storage and transportation are relatively easier and cheaper.

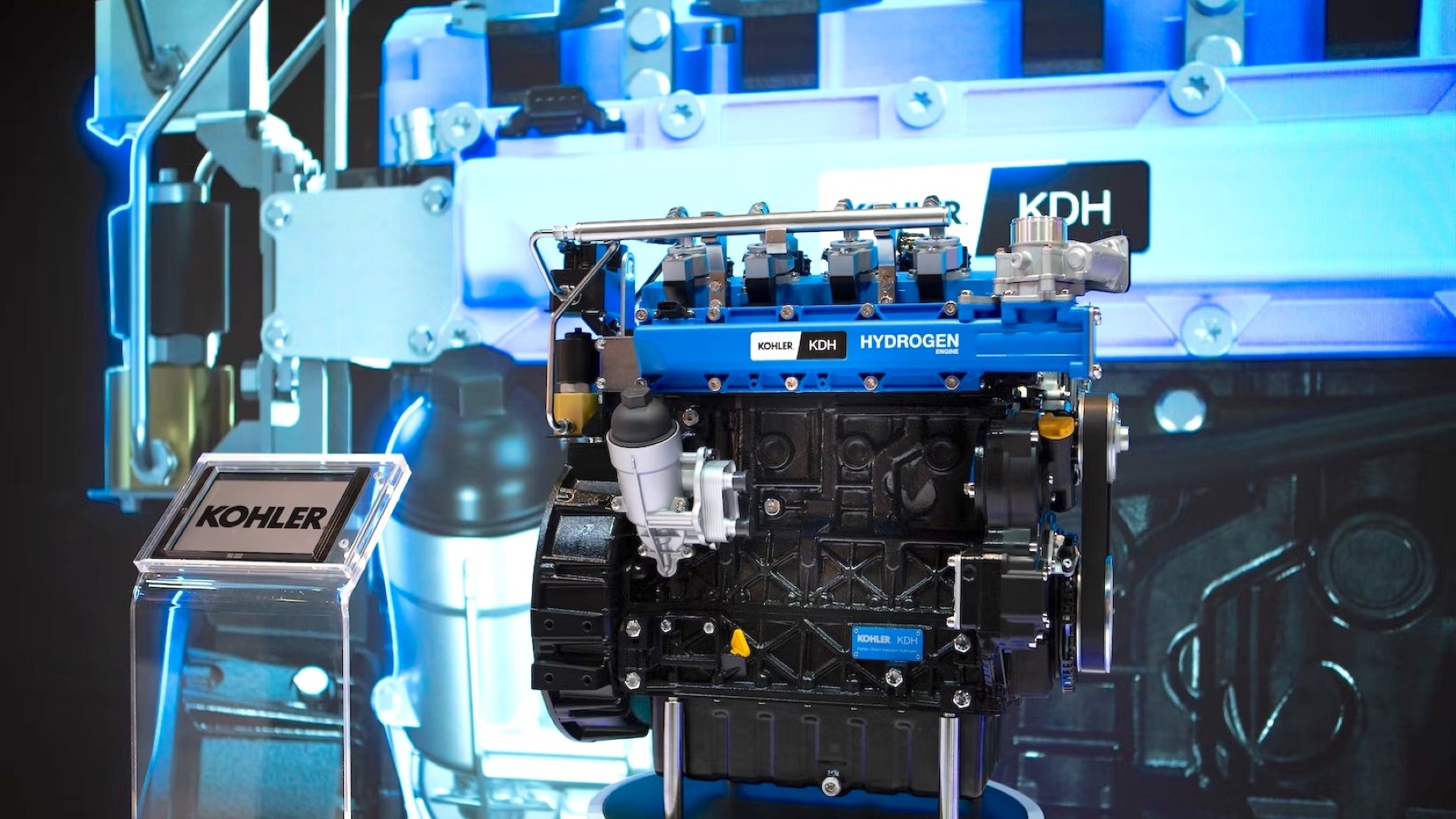

Kohler Engines, a market giant in the provision of these engines, recently unveiled their hydrogen DI engine, which comes with performance features of standard diesel engines but with no CO2 emission. Another aspect that defines these new hydrogen engines is versatility, such as Kohler’s KDH engine, which can be integrated into existing diesel engines, reducing the need for radical changes.

This drop-in solution responds to one of the major issues manufacturers face when implementing new technologies. Moreover, hydrogen has nearly zero emissions, and when combined with an aftertreatment system (ATS), it reduces other emissions such as NOx and particulate matter (PM).

Major environmental and performance benefits driving the shift to hydrogen combustion engines

Another benefit attributed to the use of hydrogen combustion engines is the environmental effect. When combusted, hydrogen forms water vapor, the main emission, which means no greenhouse gases like CO2. This is a significant step forward in addressing climate change.

The ATS technology builds on this by making the engines nearly emission-free, thus adhering to the highest environmental standards. Combustion engines utilizing hydrogen also maintain performance parameters equivalent to or better than diesel engines.

This is particularly important in the agriculture, construction, and transportation sectors, where machinery efficiency is critical to productivity. These performance metrics are well sustained by hydrogen combustion engines, making the transition between manufacturers and users very smooth.

Industries are embracing hydrogen combustion engines as a scalable, sustainable solution for the future

Hydrogen combustion engines are not just an idea for the future—they are already used across various industries. Kohler’s KDI 2504 hydrogen engine is a great example of this technology in practice, showcasing a giant step towards decarbonization without compromising power.

This new approach positions hydrogen as a multipurpose fuel capable of powering operations in industries like heavy equipment and vehicles. The most encouraging aspect of this development is its scalability. While liquid hydrogen engines require new infrastructure, hydrogen combustion engines are designed to be incorporated into existing engine systems.

Industries can adopt this cleaner, greener technology without major modifications, making it more accessible and economically viable.