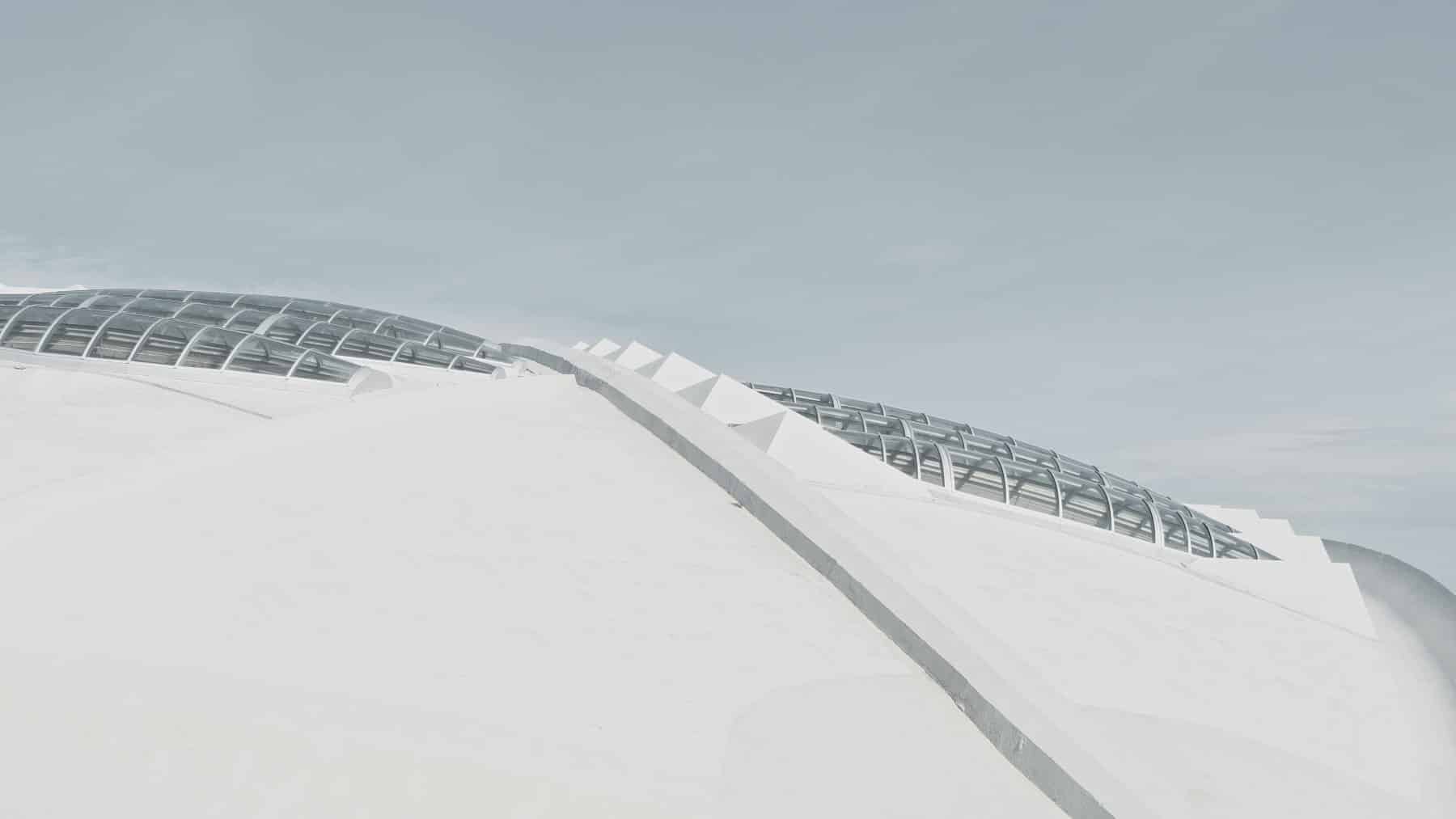

The world’s highest wind turbine, built from renewable wood materials, represents a transformative step forward in Sweden’s renewable energy development. The Swedish start-up Modvion designed this inventive design, which demonstrates major progress in modern sustainable energy technology. This exceptional venture and its influence on wind power development are explored in detail.

The game sees transformation through a new 492-foot wooden wind turbine.

The wooden wind turbine developed by Modvion reaches 150 meters (492 feet) in height, including its maximum blade length. The turbine stands near Gothenburg as a main attraction that showcases advanced sustainable engineering achievements. The 2-megawatt generator operating at the peak has begun supplying power to the Swedish electrical grid, generating energy for between 400 residential homes. The new construction embraces wood instead of steel to transform traditional turbine systems toward environmentally sustainable designs.

Due to their traditional steel composition, wind turbines constructed with steel face major operational difficulties in onshore installations. The ongoing drive to access wind power at higher altitudes requires steel support towers to extend in diameter, so transportation and setup operations become progressively challenging. Modvion constructs its wooden turbines through transportable modular pieces that can easily handle site assembly to solve steel logistics problems.

Wooden wind turbine technology provides exceptional environmental advantages, making it highly appealing to the industry. Wood surpasses steel because renewable resources capture carbon, while carbon emissions from steel manufacturing are high. Motion creates turbines with laminated veneer lumber (LVL) to achieve the required durability and flexibility while simultaneously generating carbon-negative turbine systems. These wind turbines’ entire lifecycle production and installation process functions as carbon sinks because they trap more carbon than the carbon they emit during these stages.

According to Modvion, the company will produce 100 annual wooden turbine units starting in 2027.

Using wood materials to construct wind turbines brings forth multiple financial advantages. Modvion turbines possess a modular structure that enables their movement by standard trucks due to reduced transportation expenses and logistical requirements. The lighter weight of wooden materials allows the construction of elevated wind turbines, which do not require expensive reinforcing mechanisms. Higher efficient turbine production becomes possible thanks to economic viability, enabling lower energy prices.

The company Modvion seeks to increase its capacity to build wooden wind turbines past the current yearly goal of 100 units. The company plans to develop facilities that will enable the production of 100 wooden modular turbines yearly for operations starting in 2027. ảy kiến nên của Modvion represents a potential key contributor to increasing renewable energy adoption due to the growing global wind energy sector. Ten years into the future, Modvion predicts that wooden materials will constitute ten percent of the global market share for new wind turbine development.

The renewable energy industry demonstrates strong backing and significant interest in Modvion’s project. The wind turbine manufacturer Vestas supports Modvion through investment because it sees wooden turbine potential as a supplementary function for steel wind turbines. The collaboration demonstrates how wind power companies unite to find novel methods for decreasing the carbon emissions of wind energy generation while increasing sustainability features.

Many wonder if wooden wind turbines succeed in terms of durability and operational efficiency.

The advantageous nature of wood-based turbines must be accompanied by additional development work to overcome current obstacles. Dr. Maximilian Schnippering of Siemens Gamesa has publicly expressed concerns about the modular design, which he believes will require additional trucks and personnel, as well as increased installation duration. Modvion considers the benefits of modular construction, which enhances transportability and construction speed, to outweigh the possible longevity concerns of their product.

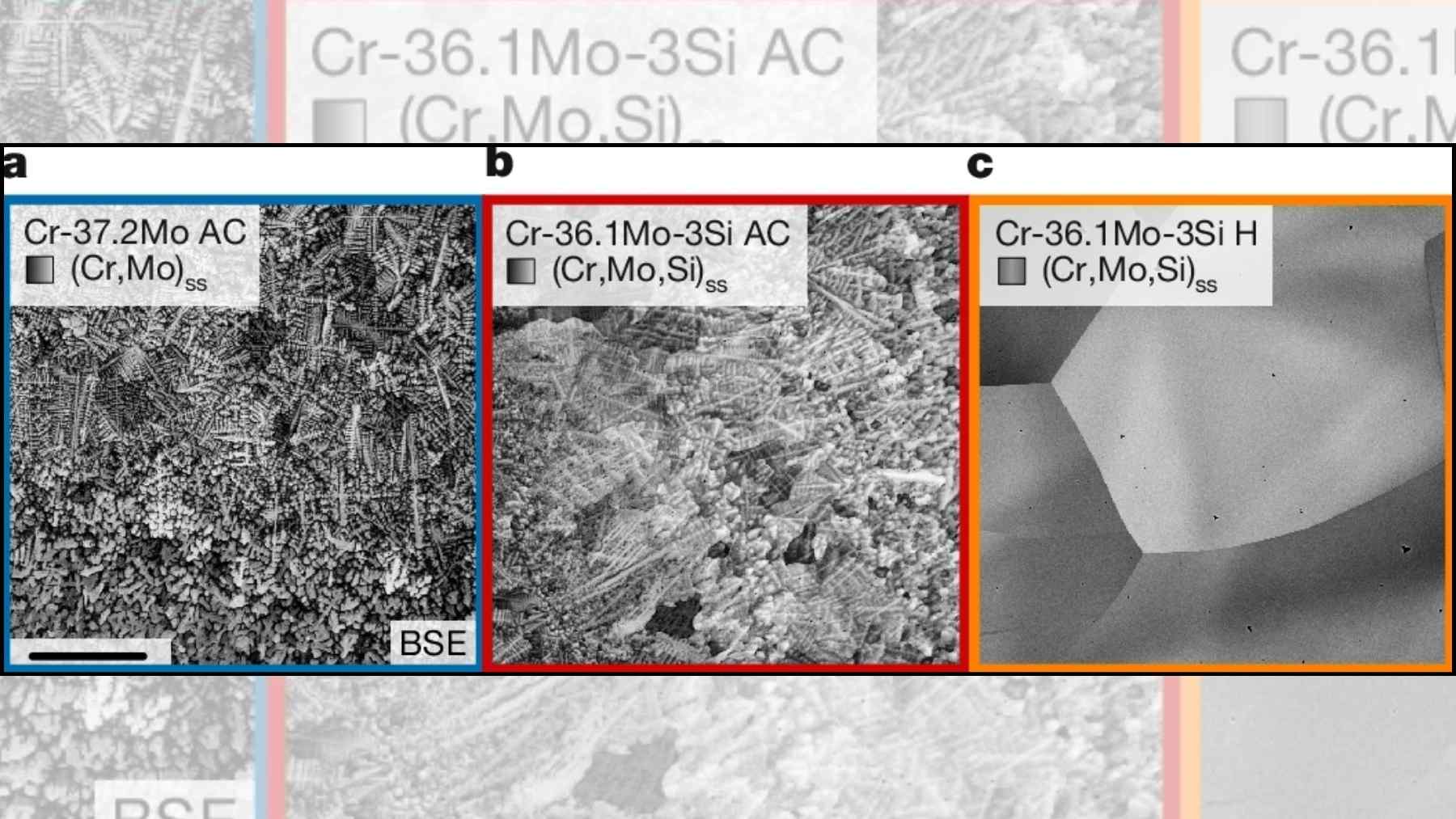

The general use of wooden wind turbines depends on their reliable durability and safe operation. Motion engineers, the turbines contain 144 layers of laminated veneer lumber, which maintains structural strength and allows flexibility against inclement weather. The company enhances its product design methods and production techniques to fulfill industry rules that enable wooden turbines to run safely over extended periods.

A wooden wind turbine built by Sweden achieved a record-breaking height above all other wind turbines while establishing its leadership role in green energy. Motion solved many technical issues faced in steel turbine production through innovative design while delivering sustainable and financially beneficial solutions. Expanding the renewable energy sector presents the possibility that wooden wind turbines will become essential in emission reduction to build a sustainable future.