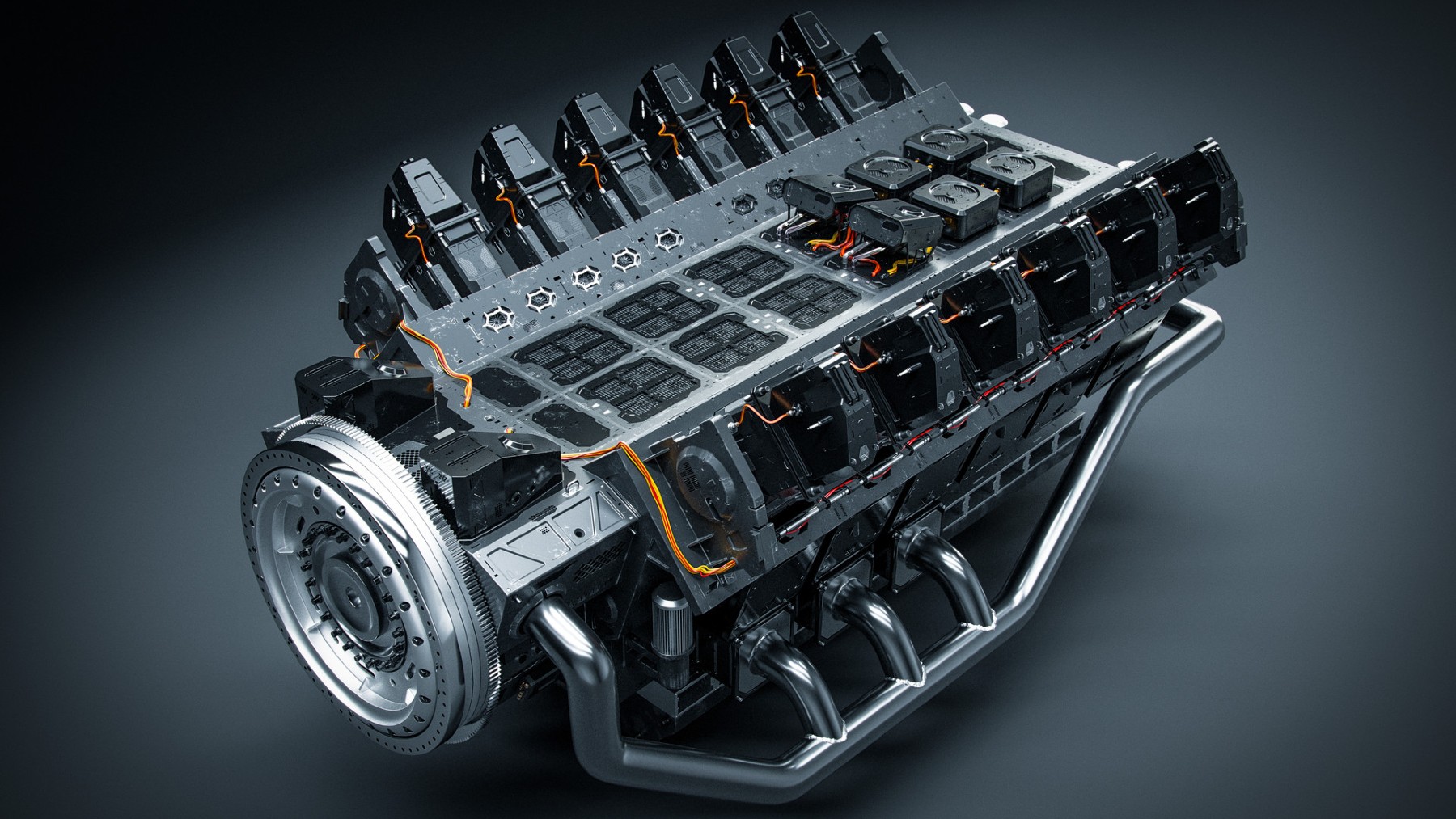

In a somewhat related yet astounding discovery, scientists working at the University of Alberta have recently revealed a new type of superalloy that could redefine the way hydrogen combustion engines could be realized. The type of alloy in question is AlCrTiVNi5; it possesses immense benefits in thermomechanical characteristics, effectively making it perfect for detailed high-temperature applications. This discovery has rendered analysts dumbfounded and keenly holds promise to alter the utilization of hydrogen as the primary fuel source.

Hydrogen engines will change forever. The nickel-aluminum alloy is the key

This newly synthesized alloy is welded or centralized and is made of aluminum, nitrogen, cobalt, tin, chromium and vanadium. This makes for an ultra-stable, low-expansion chemical make-up, that at the same time, can afford to have high fracture resistance and ‘the best of both worlds’, strength and flexibility.

These characteristics are beneficial for the materials applied in the corresponding applications, for example, the engines utilizing hydrogen combustion at high pressures and temperatures. This combustion also poses an immense hardship: it produces extremely high temperatures of 600–1500 Celsius.

The durations of which give rise to the use of some special material to hold heat and resist the corrosion of steam. The mentioned conditions have actually always caused early failure in conventional metallic coatings, and in this case, AlCrTiVNi5 is holding up the pressure remarkably.

The “secret alloy” developed at 900 °C is a Canadian invention that has experts on edge

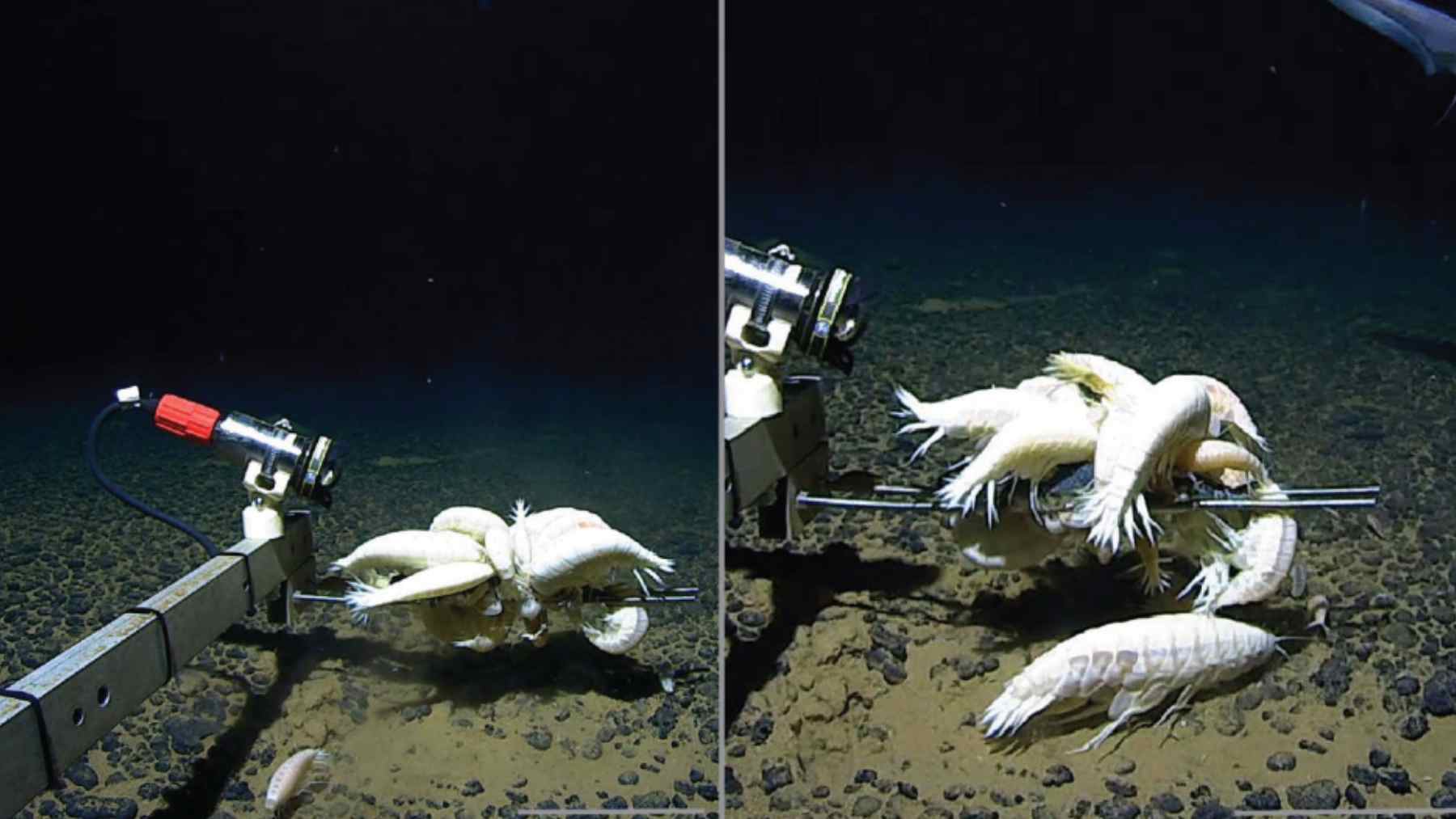

The alloy also underwent the test of exposure to 900 degrees Celsius for 100 hours without degrading, something that other alloys underwent in just 24 hours. Hydrogen is considered to be a ‘‘clean’’ fuel, and it is used because, when combusted or used in fuel cell vehicles, it produces water.

Hence, The country is involved in trying to reduce emissions in as many aspects of life as possible, like transport, heating, and industry. Hydrogen became recently an important component of the developed strategies to reduce emissions that many countries create for themselves; the mentioned example is the Canadian one, where the country has an intent to cut emissions 60% by 2050.

As shown above, hydrogen has not established a firm market today as a fuel because of issues arising from heat generated through hydrogen combustion. Most commercial hydrogen engines employ in excess of one fuel, the natural gas-hydrogen or die-hydrogen combination.

AlCrTiVNi5 could revolutionize hydrogen: It’s the end of conventional FCEVs

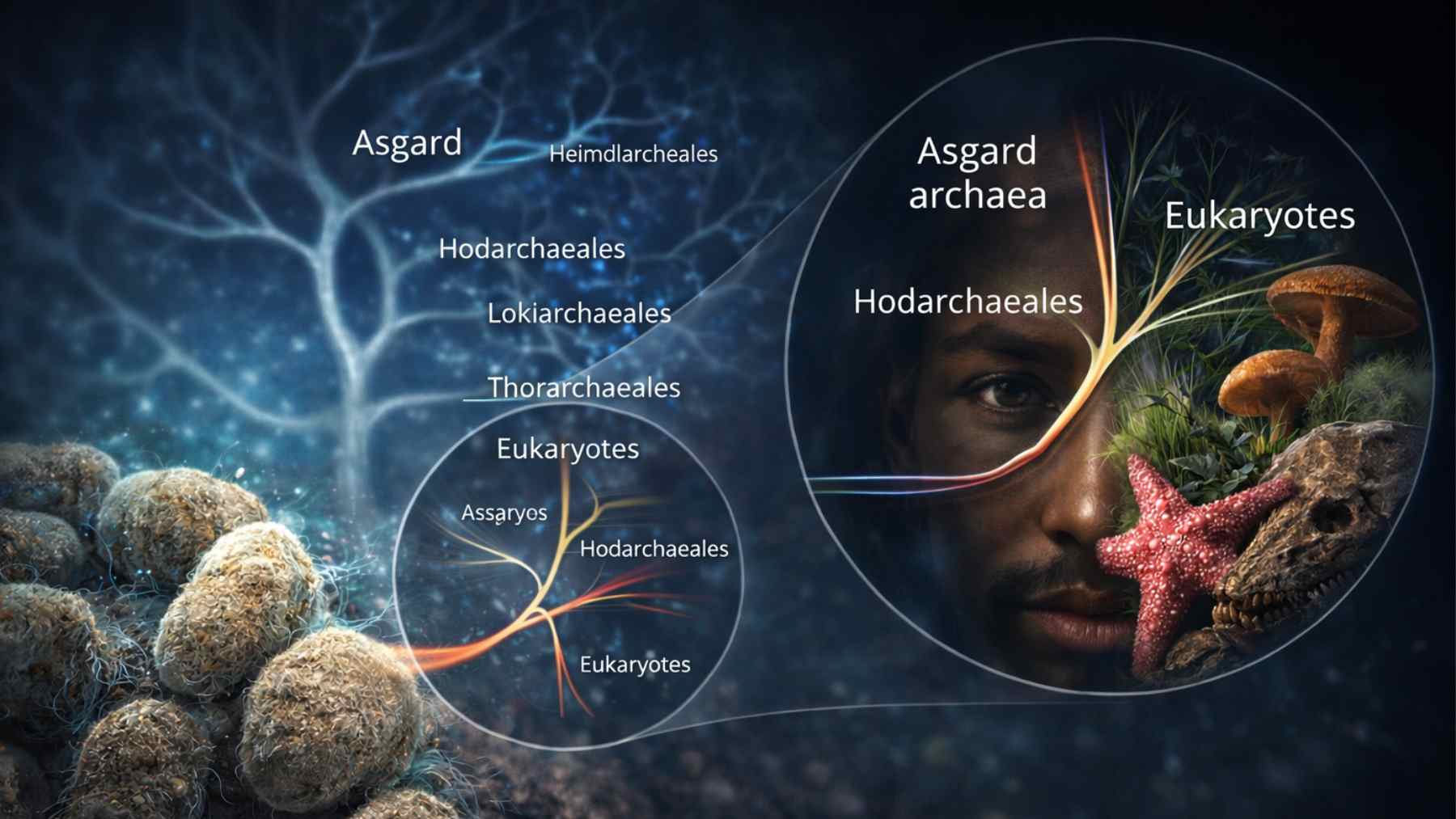

The process of arriving at the alloy AlCrTiVNi5 was based on the requirements of the absence of shortcomings in modern high-temperature use materials. This theoretical simulation was based at the University of Alberta, and the team leaders were Jing Liu and Hao Zhang.

There was a simulation analysis to come up with a new blend of metals to meet the high levels of combustion in hydrogen-based engines. The group had information regarding the behavioral pattern of different parts present in the material when it was subjected to heat, which helped them understand the features possessed by the new type of alloy being dealt with.

A great deal of research was carried out to determine the high-temperature characteristics of the alloy. After spending 100 hours in a corrosive environment at 900 degrees Celsius, this alloy lasted much longer than any commercial alkaline gas alloy. From this point of view, the high and stable activity of AlCrTiVNi5 allows us to speak about its decisive role in the formation of the world hydrogen economy.

The AlCrTiVNi5 alloy is a breakthrough in the existing high-performance material service classes. Because it can face the numerous challenges of the extreme conditions of combustion hydrogen engines, the way is open for cleaner energy in the future. Future industries and businesses that focus on using hydrogen as a major energy source, technologies, and materials, such as AlCrTiVNi5, will be of significant value in cutting this shortcoming and in nations pressing for higher sustainability.